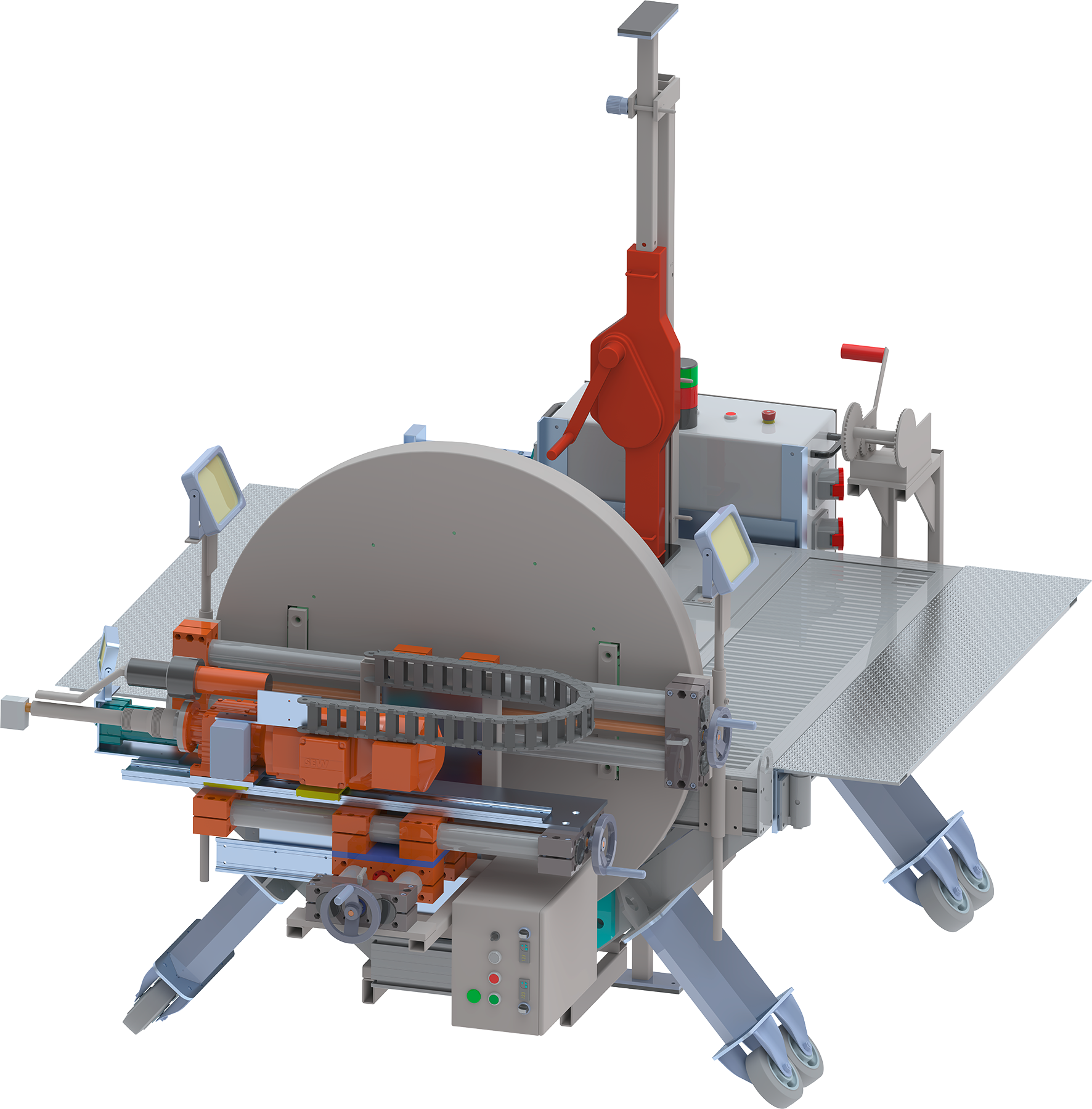

Extrusion welding machine for large diameter pipes

from Ø1200 to 3500mm

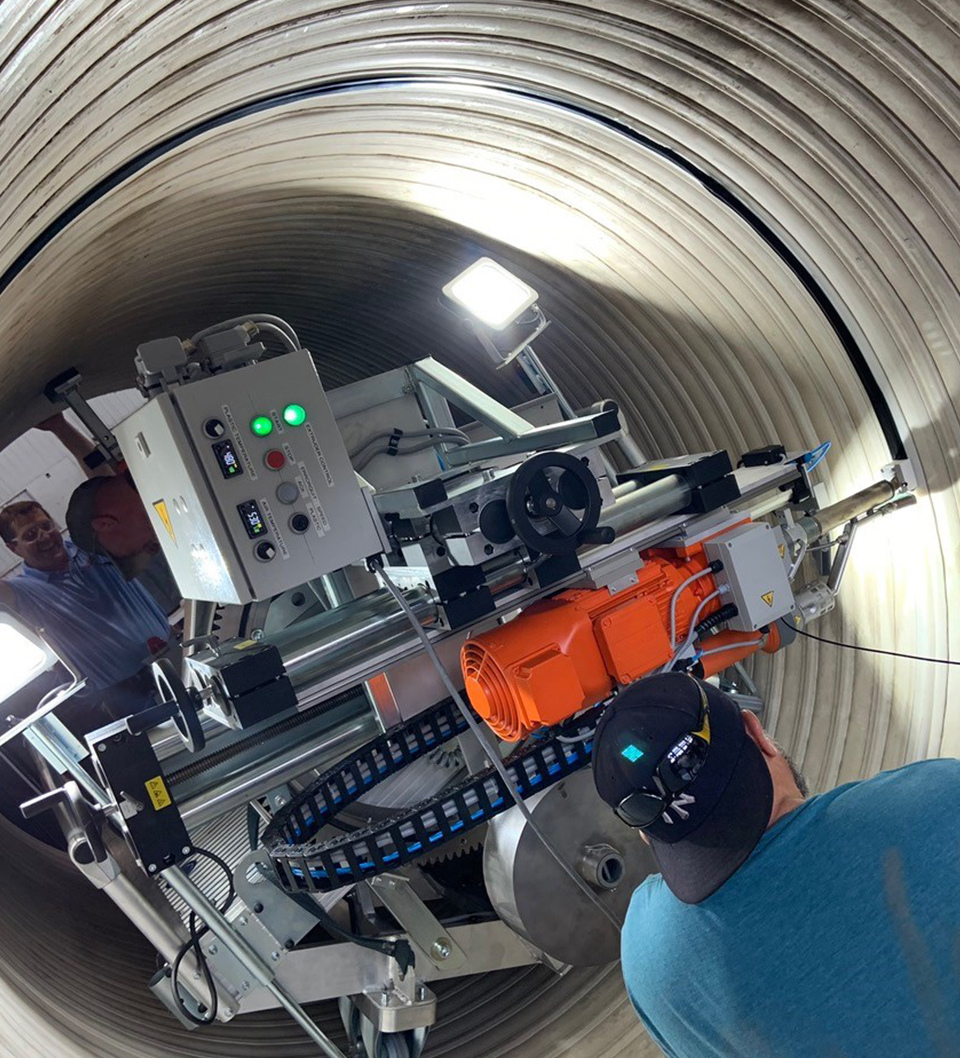

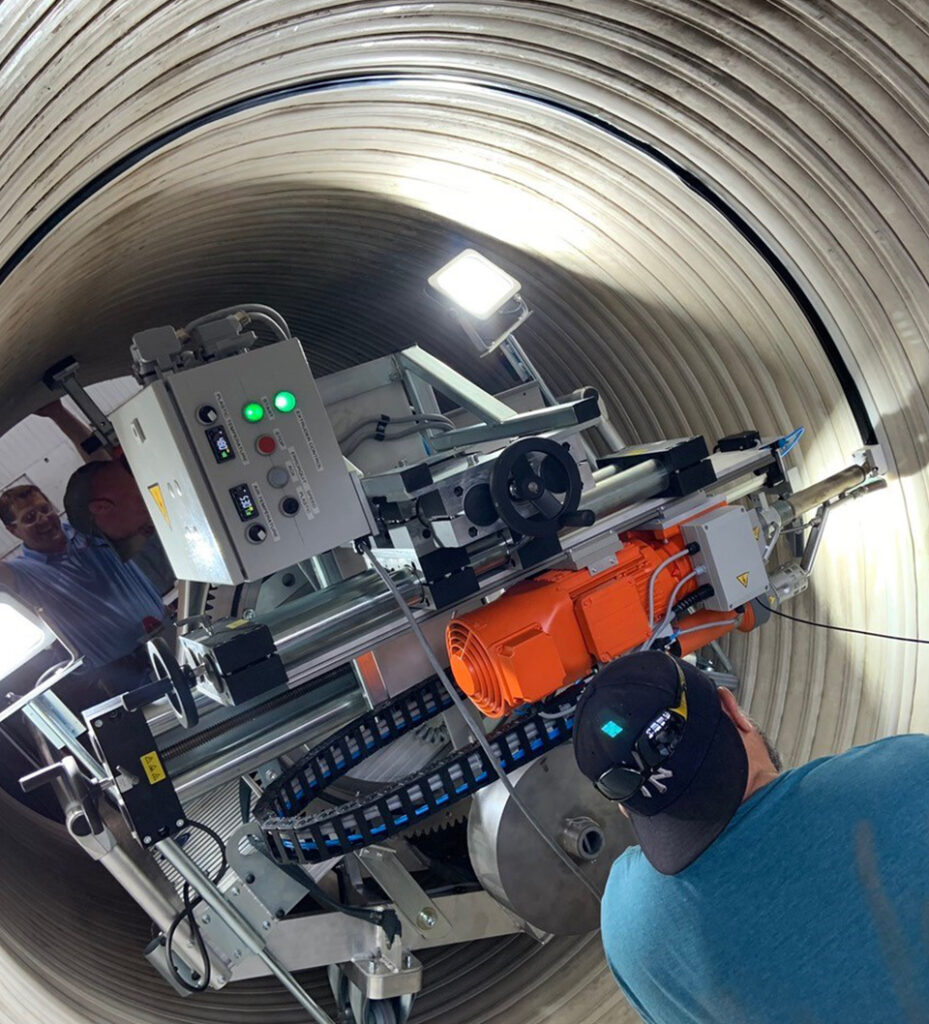

Extrusion welding machine is designed for automated inner welding of large diameter pipes from Ø 1200 mm up to 3500 mm. Core of the machine is a solid, steel frame – platform with 4 sets of wheels. In order to adapt height to axis of pipe, wheel supports have to be changed accordingly. Positioning and immobilisation is done by meand of top bar which has to be set and fixed in a proper position.

Machine is custom-built in following versions (pipe Ø mm): 1200, 1400, 1500, 1600… up to 3500 mm.

Construction

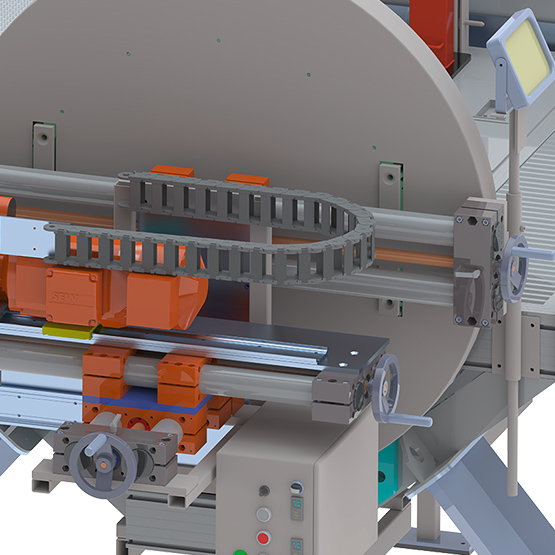

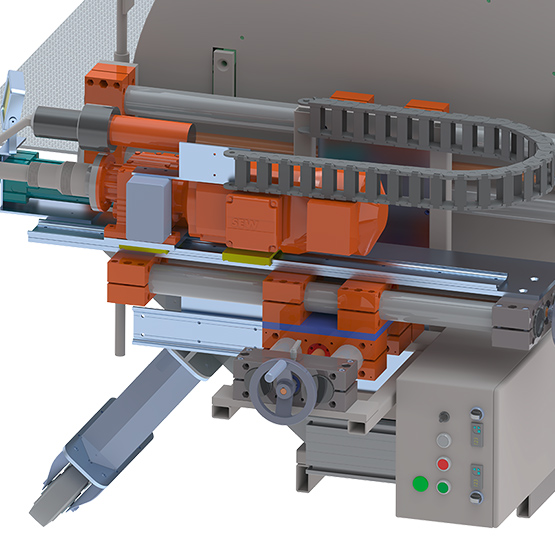

Following components are located at the front of the machine: drive motor with gearbox, a gear wheel adn control panel with frequency controller. To the gear wheel an adjustable arm with tool holder and pneumatic cylinder are mounted.

Both arm and cylinder are adjustable radially (towards the pipe wall). This telescopic arrangement ensures that the extruder can be adjusted to the minimum and maximum pipe diameter. Tool mounting plate may be equipped either with extruder or 8 mm cutting spindle mounting.

Appplication of pneumatic system ensures uniform, continous welding pressure on the whole surface.

Operation

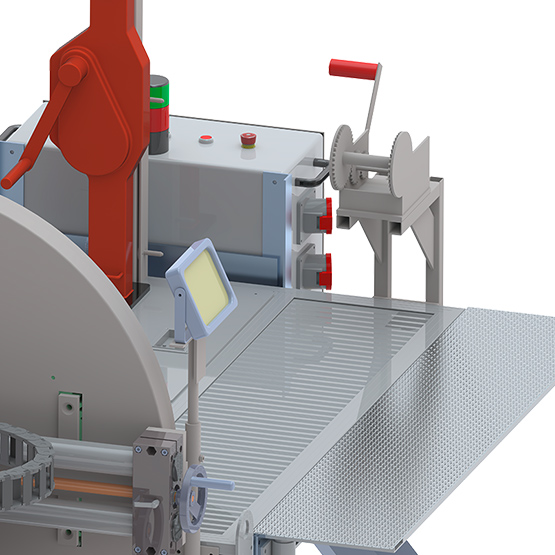

Machine is operated via integrated control panel. Control panel includes necessary switch fuses, Start-Stop-buttons, emergency stop and power socket for other electrical devices like the extruder, a working light and a small air compressor. On request, machine may be also equipped with platform for operator who may adjust welding path by means of hand-operated adjustment wheel.

Pipe sizes

Machines are tailored made. For optimum performance and most accurate quotation, please provide us with additional information about: pipe diameters to be welded, type of pipe, and material.

Welding shoes

Required shape of extruder welding shoe depends on thickness of walls to be welded, type of welds (overlapp vs. X/V) and groove geometry. It means that for different applications, different welding shoes are compulsory. Therefore, machine we will be delivered with extruder equipped with one PTFE blank welding shoe that has to be machined for required application.

Parameters

- 12kg/h extrusion capacity with 6mm extrusion rod on spool

- Air cooled brushless motor

- Speed control by frequency-converter

- Preheating device with brushless motor

Optional milling device

In general, edges of pipes must be mechanically machined prior to welding. Reason for that is to remove oxidized layer of plastic especially when the pipes where stored for a longer period of time and to prepare flat surfaces for required geomentry of the weld. The goal is to provide high quality welds of maximum strenght and tightness.

Our machine may be delivered with 8 mm tool holder for industrial end mill.

| General | Unit | |

| Revolutions per min (extruder arm): | Min -1 | 0 to 0.4 |

| Operating temperature range | C° | 0 to 50 |

| International Protection: | IP00 | |

| Appliance class: | I | |

| Input/Mains | ||

| Nominal voltage | V | 400 AC |

| Nominal frequency | Hz | 50/60 |

| Nominal current | A | 3×11 |

| Power consumption: | W | 7000 |

| Plug type: | CEE 400V 16A | |

| Dimensions, weights and packaging | ||

| Product dimensions L×W×H | mm | 120″: 2800 x 2900 x 2940 96″: 2800 x 2000 x 2380 84″: 2800 x 2000 x 2360 72″: 2760 x 1475 x 1630 |

| Product weight | kg | Approx. 600 |

| Packaging dimensions L×W×H. | mm | Approx. 3200 x 1800 x 1850 |

| Packaging material: | Wood | |

| Packaging type: | Box | |

| Transport weight: | kg | 650 |