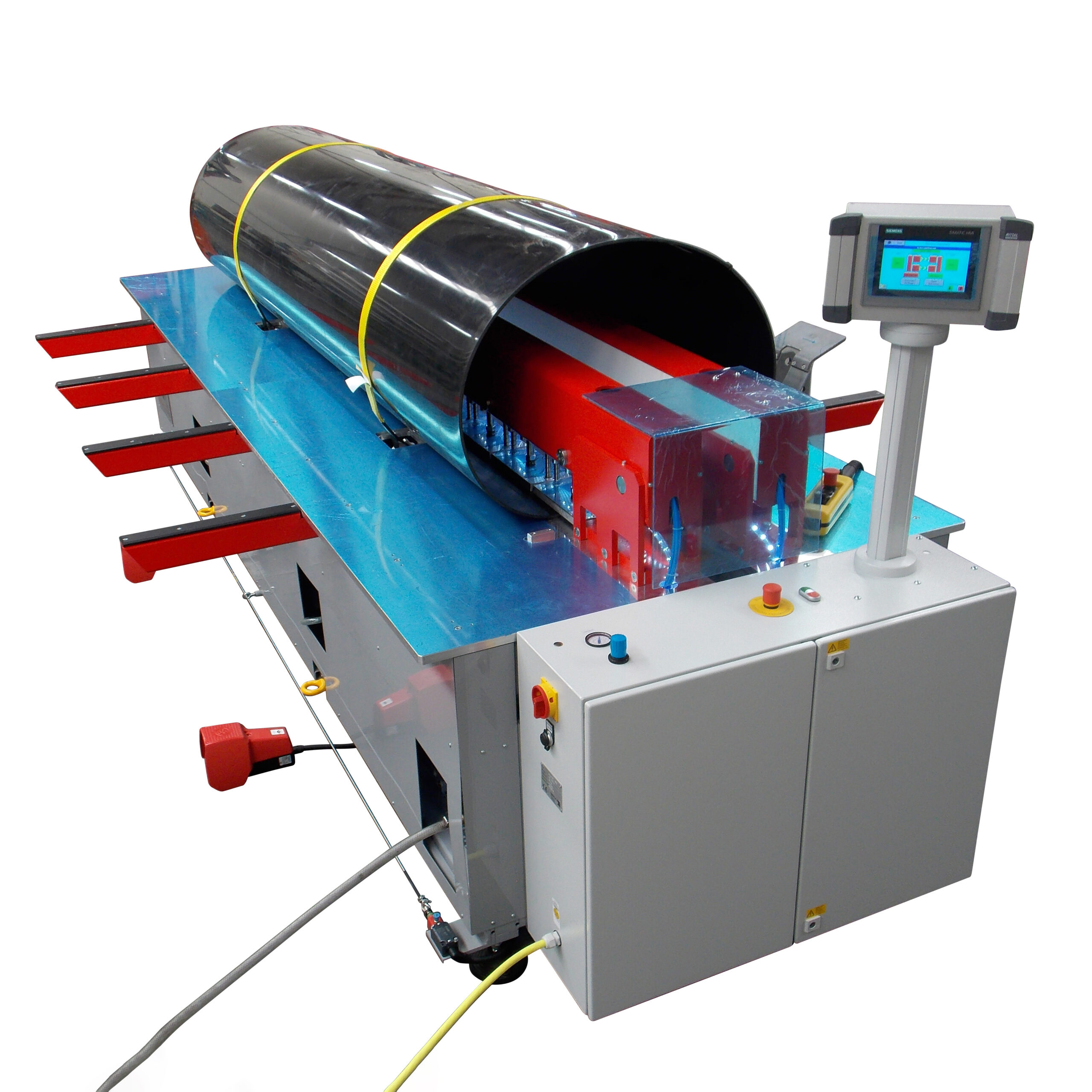

Ingenia P-SW

Automatic butt welding machine for plastic sheets

Ingenia P-SW is a fully automatic butt welding machine for plastic sheets of thickness 3-30 mm (optionally 60 mm). P-SW is the most technically advanced butt welding machine designed for intensive welding of plastic sheets according to DVS standards. Already in basic configuration, P-SW series are equipped with 2 clamping zones at each side of the table, aluminum clamping plates with anti – skid surface, service friendly single valve system, Siemens PLC with welding profiles and CNC table force control.

Features

Available versions with 2000 mm, 3000 mm, 4000 mm and 5000 mm welding width

Automatically executed welding process according to predefined recipes (DVS guidelines)

CNC controlled process forces with proportional valve

2 welding zones at each side of the table - may be operated separately

Remote controller or Siemens touch screen

Heavy-duty, stress resistant frame

Milled surfaces of aluminum tables prevent from moving sheets

PE coated side arms

Aluminum pressure plates with anti-skid surface

Emergency limit switch

Cold start protection

Options:

LED illumination of welding zones

Long side arms with ball bearings

Engraved scale in surface of welding tables

Force measuring and regulation system

Foot pedal or remote controller for clamping

Acoustic signal

Pneumatic lever to rise sheets after welding

Adjustment for welding profiles and hollow sheets < 65 mm

Additional clamping zone (3 instead of 2) at each side of machine

Unit for angled welds 90° (L)

Unit for T-welds (only in combination with unit for angled welds 90°)

Sheet winding unit for automated production of cylindrical containers

Video:

| 20.30 P-SW | 30.30 P-SW | 40.30 P-SW | 50.30 P-SW | Unit | |

|---|---|---|---|---|---|

| Length | 3200 | 4200 | 5200 | 6200 | mm |

| Width | 1200 | 1200 | 1200 | 1200 | mm |

| Height / Height of the working table | 1200/900 | 1200/900 | 1200/900 | 1200/900 | mm |

| Weight, approx. | 1,6 | 2,4 | 2,9 | 3,6 | t |

| Working range | |||||

| Max. working width | 2050 | 3050 | 4050 | 5050 | mm |

| Material thickness | 3-30 | 3-30 | 3-30 | 3-30 | mm |

| Working bore height | 47 | 47 | 47 | 47 | mm |

| The minimum diameter of the cylinder | 500 | 500 | 500 | 600 | mm |

| Number of clamp zones per beam | 2 | 2 | 2 | 2 | |

| Power | |||||

| Electric | 230/400 V 3/N/PE 50-60 Hz | ||||

| Power | 3 | 6 | 6 | 9 | kW |

| Connector | 16A | 16A | 16A | 32A | CEE |

| Pneumatic | 7 | 7 | 7 | 7 | bar |

| Forces | |||||

| Clamp at 7/10 bar | 15 / 25 | 26 / 37 | 35 / 50 | 47 / 65 | kN |

| Minimum pressure during welding | 925 | 1375 | 1825 | 2725 | N |

| Maximum pressure during welding | 9225 | 13725 | 18225 | 22725 | N |

| Heating unit | |||||

| Heating strip | 30 x 80 mm with teflon coating Tmax=260o | mm | |||

| 30.40 P-SW | 40.40 P-SW | 50.40 P-SW | Unit | |

|---|---|---|---|---|

| Dimensions | ||||

| Length | 4200 | 5200 | 6200 | mm |

| Width | 1200 | 1200 | 1200 | mm |

| Height/ height of the working table | 1200/900 | 1200/900 | 1200/900 | mm |

| Weight, approx. | 2,6 | 3,2 | 3,9 | t |

| Working range | ||||

| Max. working width | 3050 | 4050 | 5050 | mm |

| Material thickness | 3-40 | 4-40 | 4-40 | mm |

| Working bore height | 77 | 77 | 77 | mm |

| The minimum diameter of the cylinder | 600 | 600 | 600 | mm |

| Number of clamp zones per beam | 2 | 2 | 2 | |

| Power | ||||

| Electric | 230/400 V 3/N/PE 50-60 Hz | |||

| Power | 6 | 6 | 9 | kW |

| Connector | 32A | CEE | ||

| Pneumatic | 8-10 | 8-10 | 8-10 | bar |

| Forces | ||||

| Clamp at 7/10 bar | 51 / 85 | 68 / 113 | 85 / 140 | kN |

| Minimum pressure during welding | 1830 | 2430 | 3030 | N |

| Maximum pressure during welding | 18300 | 24300 | 30300 | N |

| Heating unit | ||||

| Heating strip | 30 x 80 mm with teflon coat Tmax=260o | mm | ||

| 30.50 P-SW | 40.50 P-SW | 50.50 P-SW | Unit | |

|---|---|---|---|---|

| Dimensions | ||||

| Length | 4200 | 5200 | 6200 | mm |

| Width | 1200 | 1200 | 1200 | mm |

| Height / Height of working table | 1200/900 | 1200/900 | 1200/900 | mm |

| Weight, approx. | 2,6 | 3,2 | 4,2 | t |

| Working range | ||||

| Max. working width | 3050 | 4050 | 5050 | mm |

| Material thickness | 4-50 | 4-50 | 4-50 | mm |

| Working bore height | 77 | 77 | 77 | mm |

| The minimum diameter of the cylinder | 600 | 600 | 700 | mm |

| Number of clamp zones per beam | 2 | 2 | 2 | |

| Power | ||||

| Electric | 230/400 V 3/N/PE 50-60 Hz | |||

| Power | 6 | 6 | 9 | kW |

| Connector | 32A | CEE | ||

| Pneumatic | 7 | 7 | 7 | bar |

| Forces | ||||

| Clamp at 7/10 bar | 51 / 85 | 68 / 113 | 85 / 140 | kN |

| Minimum welding forces | 1830 | 2430 | 3030 | N |

| Maximum pressure during welding | 22857 | 30375 | 37950 | N |

| Heating unit | ||||

| Heating strip | 30 x 80 mm with teflon coat Tmax=260o | mm | ||